At the cynosure of your cymbal’s tone, the widely discussed, and wildly differentiating: alloy. The alloy is the blend of metals that makes up your cymbal and shapes its sound possibly more than any other factor. Generally speaking, most cymbals are made from any variety of copper-based alloys. I’m just going to go through some of the basic differences, as the spread of metal mixtures today is wider than ever.

Brass Cymbals

Brass is approximately 38% zinc and 62% copper. These percentages can range by narrow margins, but are generally consistent. The most popular use for brass in cymbals is in starter cymbals. The primary reason for this is the easy access to brass as a sheet metal, which removes the entire first half of the cymbal making process.

Brass cymbals are almost universally made by a machine, en masse to be shipped all over the world at a low cost. The most obvious plus side to this is providing beginner drummers and drummers on a budget something to play with. Unfortunately though, brass cymbals tend to sound much duller than their siblings, and they lack a wide frequency range that you hear in higher-end cymbals.

B8 Alloys

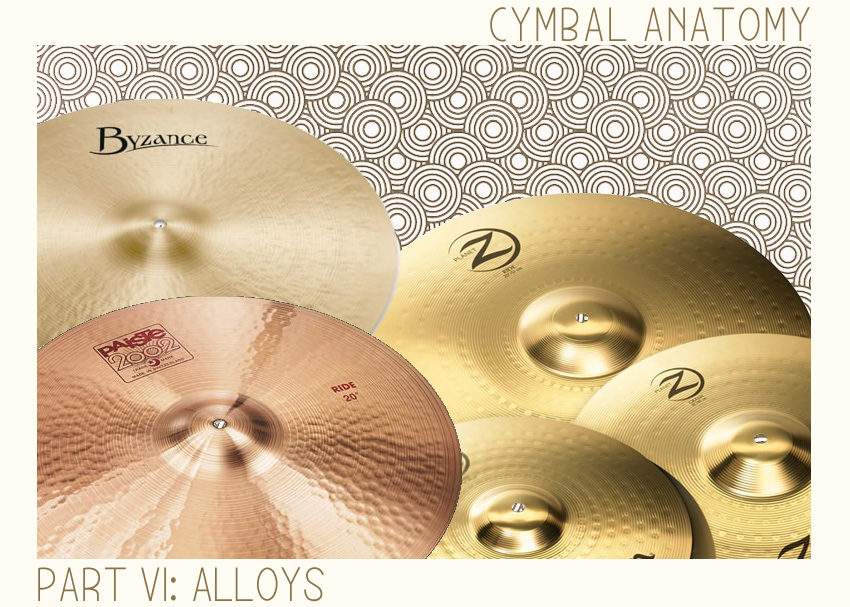

The B8 alloy (8% tin, 92% copper) was the cymbal industry’s response to bring cost down on cymbal manufacturing without sacrificing tone. Some drummers may see B8, and instantly think of Sabian’s B8X series, but this is a creation not just for drummers on a budget. Take a look at the Paiste 2002 series for instance, most notably played by John Bonham. The best thing about a B8 cymbal is its readiness to by struck hard, making them great for aggressive rock or metal settings.

One thing that could be positive or negative about B8 cymbals (depending on the application) is their very specific frequency response. They tend to have no lower frequency response, and cut off some of the higher frequency response. This makes them very bright overall, which is not explicitly a bad thing.

B20 Alloys

When cymbal shopping, one of the first things you will notice is the sweeping range of prices. When you are looking at a cymbal that is particularly expensive, odds are it is made of B20 bronze (20% tin, 80% copper). Because of its construction, bell bronze is not readily available in sheet metal form, and therefore must be cast and shaped into a smaller puck, and shaped from there (typically by hand-hammering, but occasionally by machine).

Due to the smaller batch work needed for this alloy, and all of the processes that must be completed by hand, you’ll notice they tend to be of a higher value. B20 bronze by and large has the widest frequency response, which gives it its full tonal characteristics and its responsiveness to playing approach. B20 bronze also happens to be one of the oldest cymbal manufacturing techniques, making it a standard for traditionally crafted cymbal series.