Asheville, North Carolina is a mecca for artists and musicians of all stripes — but it’s especially dear to the hearts of analog synthesizer enthusiasts. That’s because Asheville is home to the Moog synthesizer factory, where 61 full-time Moog Music employees work to carry on the legacy of the company’s famous founder, Dr. Bob Moog.

Everything Moog does is under this roof — from hand-building instruments, to design and engineering, to sales and marketing, to shipping, to servicing old synths. There’s also the Moog Sound Lab, a multimedia recording studio where touring musicians make a point of stopping by to perform with Moog gear.

Have you ever seen so many Moog synths in one place? Take a look inside the Moog synthesizer factory in our photo gallery — and be sure to look through our notes below!

Meet the Moog Mother-32 synthesizer

- Once each Voyager XL is assembled, a technician opens up the case and sets about 30 different calibration points down to the millivolt.

- Moog Sub Phatty and Sub 37 synthesizers stand at attention under the American flag.

- If any analog components in these Moog Sub Phatty synths are going to go bad, it’ll happen during this 48-hour burn-in process.

- The most Minimoog Voyager XL synthesizers we’ve seen in one place — including both the Tolex edition and wood case models.

- One of Moog’s newest products, the Theremini pairs a digital sound engine with the analog control of the Theremin antennae.

- A look at the circuit board inside the Theremini’s case.

- Moog’s warehouse is small — they typically don’t keep inventory on hand. Instead, they build instruments (like these Sub 37s and Sub Phattys) as customers (like zZounds) order them.

- The aliens have landed. It’s a Moog Theremini invasion!

- Moog technicians at work, surrounded by carts of Sub 37 synthesizers in progress.

- Each Moog synthesizer — like this Sub 37 — goes through a burn-in process of 48 hours.

- Some Moog Sub 37 synths are in the process of burning in, while others await their power harnesses and endplates.

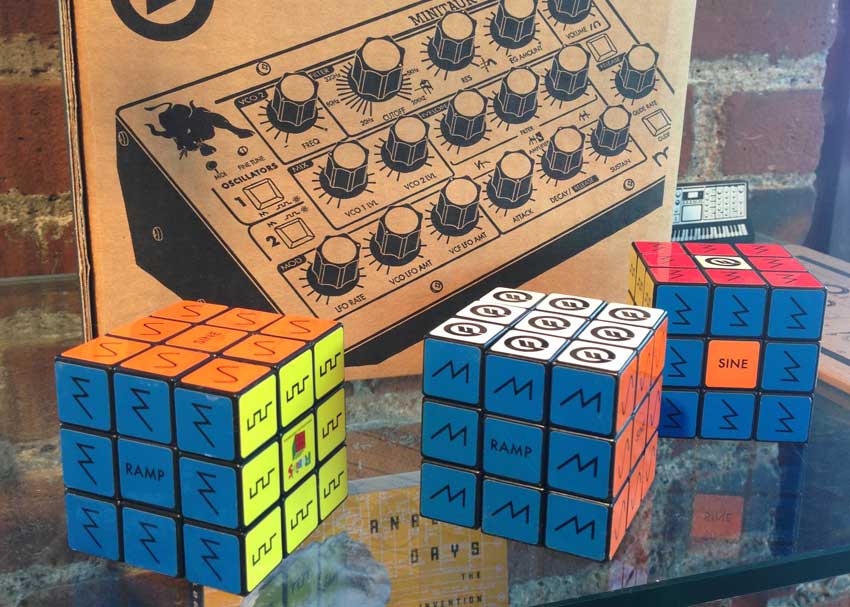

- At the front of the factory is the Moog Store, where customers can walk in and try out the latest and greatest Moog gear.

- The Moog Store is full of cool collectibles. There’s even a Moog Rubik’s Cube — if retro-style toys are your thing!

- A rack of Moog Moogerfooger effects pedals, ready to be plugged in and “burned in” for 48 hours.

- Upstairs in the Moog Sound Lab, guitarist Josh Chassner tries out a few Minifooger effects pedals for a video shoot.

- Anyone who’s ever built a cable (or an analog modular synthesizer) by hand will recognize the soldering iron and multimeter as tools of the trade.

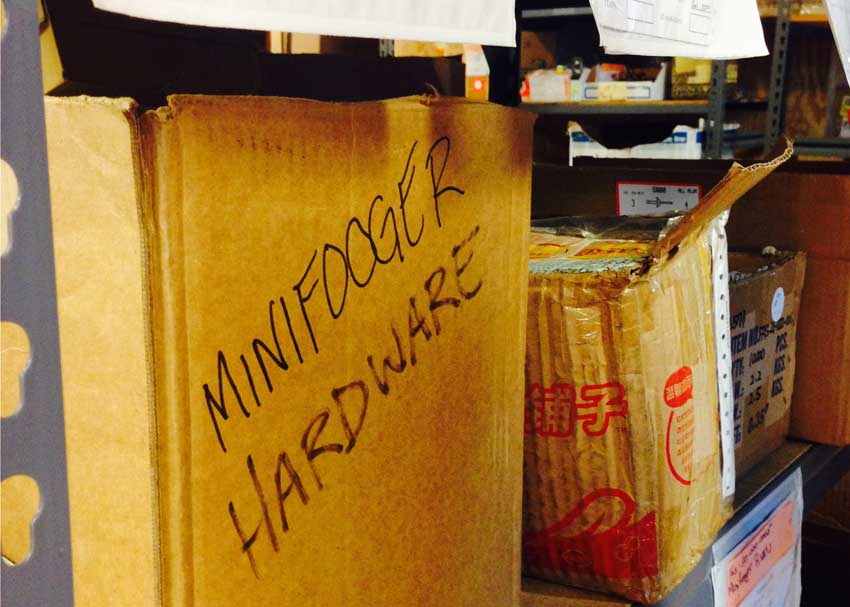

- Minifooger effects pedals go through the same detailed assembly, calibration, and testing process as Moog’s flagship synths.

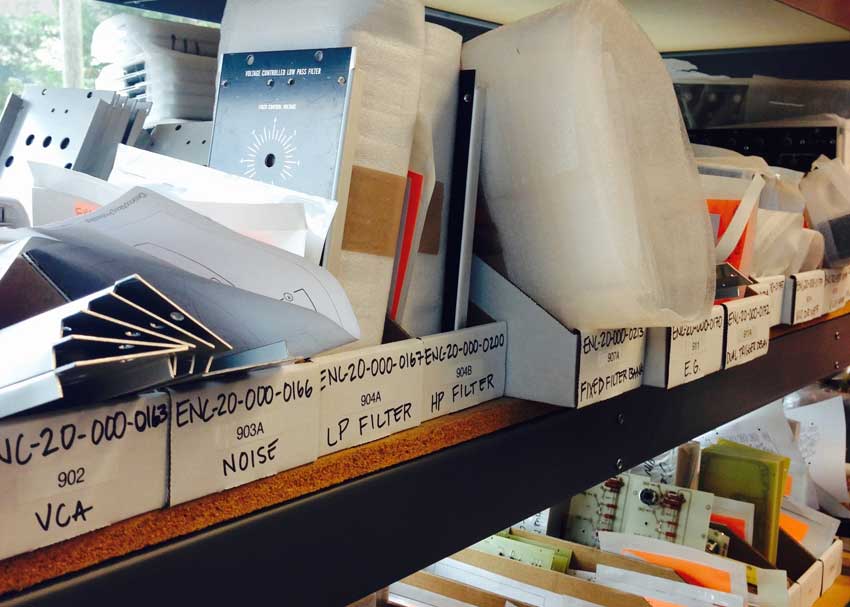

- These shelves hold faceplates for Moog’s modular synthesizer modules — ready to be assembled by hand. The sequencer module alone takes a skilled technician about 4 days to build from start to finish.

- Bob Moog built his first Theremin at age 14, and continued making them throughout his career. Moog is still the leading manufacturer in the world for Theremin instruments — like these Etherwave models.

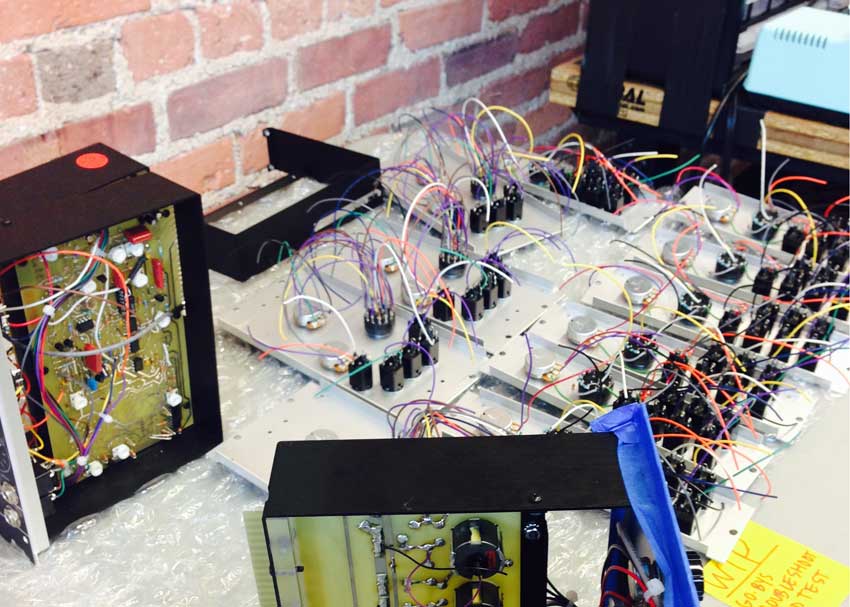

- Moog technician Nick Montoya’s workbench, where he builds modules for System 55, System 35, and Model 15 modular synths. Sorry, we can’t show you those top-secret documents…

- Each module in Moog’s modular synths is hand-wired here. Where possible, Moog techs use New Old Stock components made in the 1960s and ’70s.

- Visit the Moog factory? We don’t mind if we do.

- Installing knobs is just one step in the process of building a Moog Sub 37 synthesizer.

- When you’re playing Moog gear, it’s always nice to get an extra hand dialing in your sound from the Moog employees that made it.

- Good keyboards only. We’d expect no less at the Moog factory!

- After you assemble a Voyager synth, don’t forget to wipe the sweat off the keys…

- You’d be “Happy” too if your job was building Minimoog Voyager synths — the latest evolution of a line of instruments started in 1978.

- The wood for Voyager cases is sourced from Sparta, Tennessee — one state over from the Moog factory.

- Moog technician TJ carefully matches wooden pieces for each Voyager case, then installs the left-hand controllers — pitch and mod wheels — which are built right here in the factory.

- Each Minimoog Voyager goes through a detailed assembly process, with parts sourced locally whenever possible. Even the main circuit board is manufactured here in Asheville.

- A technician assembles a Theremini theremin — the only current Moog product that features a digital synthesis engine.

- Installing the back plate on a Moog Sub 37. The production line runs day and night shifts, just to keep up with demand for this popular synth.

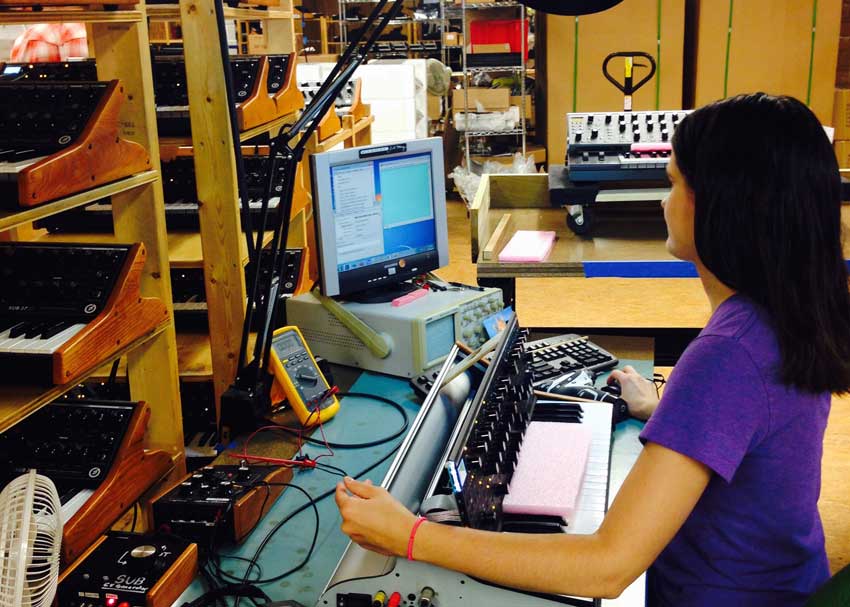

- A Moog technician uses a multimeter, an oscilloscope, and MIDI software to test and tune this Sub 37 synthesizer.

- After each instrument has been calibrated and put back together, a technician does a final check to ensure that it sounds and feels as it should. If all goes perfectly, the process takes about an hour and a half.

- A technician builds a Minifooger MF Chorus pedal — Moog’s pedals aimed at guitarists.