This post is part of a “Shure Week” (August 6-13) series celebrating the release of the new MOTIV line of USB and iOS microphones and interfaces. Check with us through the week to learn more about Shure!

Go In-Depth with the MOTIV line

Nine Things You Might Not Know About Shure

You’ve probably heard tales of — or experienced for yourself — the almost-mythic durability and resilience of Shure microphones.

An SM58 mic takes a 10-foot drop off stage, or gets crushed under a touring van. You spill a whole can of fizzy Coca-Cola on your SM57 in the studio. But whether bent, burnt, or bathed in sticky liquid, that same mic has gotten you through the gig. And these results are no fluke — the legendary durability of Shure mics is all thanks to the meticulous, exhaustive, and comprehensive quality testing done by Shure engineers.

A bruised SM58. We didn’t take this photo, but we bet the mic still sounded great!

Upon a recent tour of the company’s headquarters in Niles, IL, (pictured above) the zZounds crew got an inside look into Shure’s product testing. Check out our recap below, and if you have any stories of Shure durability to share, let us know in the comments below!

Start With Sound

Shure is not only meticulous in durability testing, but in sonic testing, too. To get the most accurate assessment of its microphones, Shure tests them all in its anechoic chamber. The opposite of an echo chamber, an anechoic chamber is a room meant to deaden all sound. The room is soundproofed inside and out, and every surface is padded with sound-absorbing material, so there are zero echoes or reverberation.

- Looking down on to the mesh wire floor suspended above the soundproofed actual floor of the anechoic chamber.

- Ceiling meets wall in the anechoic chamber.

- The RF chamber at Shure

In this super-quiet room, a loudspeaker plays back test tones and white noise at various volumes, while a microphone picks up these signals. Monitors outside the chamber relay what the microphone is “hearing,” testing the mic’s sensitivity, frequency response, and polar pattern.

In the RF (radio frequency) anechoic chamber, the walls are reinforced with materials that block all radio, TV or wireless phone signals. In this chamber, Shure can test their wireless audio systems in a closed environment, free from interference from any other wireless device.

Test, and Test Again

For the most part, Shure’s testing of new products follow a proven process. Shure Senior Mechanical Engineer Andres Huertas said that standard procedure includes environmental testing, use-based testing, and ensuring operation under various conditions including hot/cold temperatures, humidity, and moisture exposure. It’s a standard of durability that goes back to Shure’s WWII heritage, when the company made military-grade communications equipment that not only needed to survive war zones, but extreme temperature changes.

- A low-temperature storage chamber designed to ensure Shure products survive winter conditions.

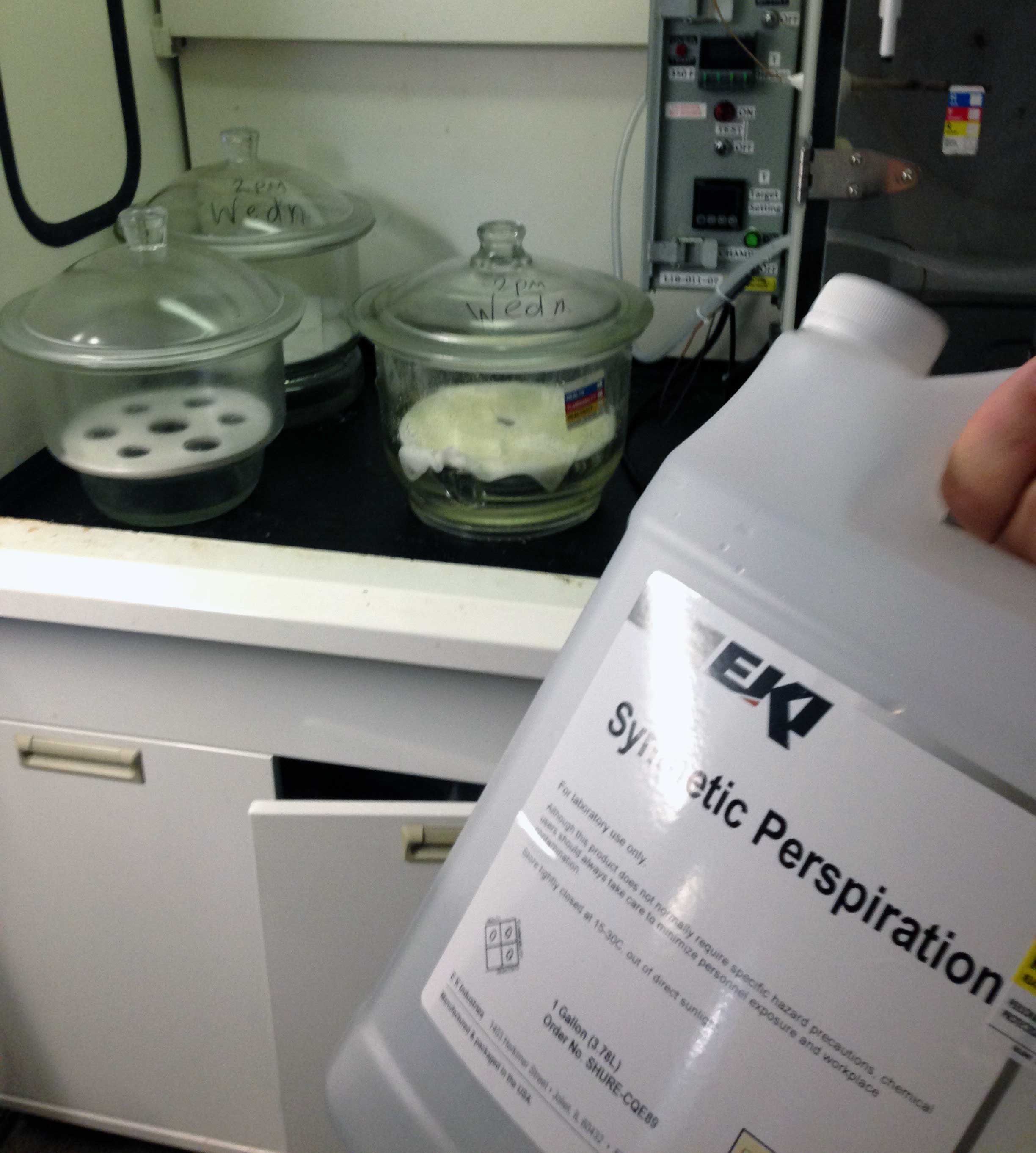

- A container of synthetic perspiration used to test how microphones and bodypacks stand up to sweaty performers.

- A mic-drop tester, designed to simulate a microphone falling off the stage.

“Those tests can take multiple days, trying to make sure the product comes back to being perfect at the end,” Huertas said. “Then we always have our other tests; so while those are cooking and baking and freezing, we do our other tests, drops and cycling and any kind of use case test that we might do to make sure the buttons work no matter what.”

It’s not enough for a Shure product to simply survive these conditions: Shure engineers evaluate products again after stress testing to ensure they retain the same sound quality. When you pick up that SM58 off the stage, its grill dented (as it’s designed to be) in the spot where it hit the corner of your floor monitor, and you put it back on the mic stand and hear your voice just as clear as it was before — that’s when all that testing pays off.

Yet even after a product hits the market, testing is far from over. Though testers can get accurate estimates of a new product’s lifespan from testing they continue to audit products to prove they will retain performance one year, five years, 10 years or more down the road.

“It’s something that we do to make sure our products maintain the level of quality that we expect over time, to make sure nothing sneaks up on us and kind of re-evaluate and look to see that our product is exactly what we expect and what our customer deserves,” Huertas said.

Although the standard tests remain fairly the same across all products, some, like those in the new MOTIV series, require some tweaking during tests for their unique applications.

“With the MV5 specifically, one thing we had was a tripod mount which is a little different,” Huertas said. “So we kind of adjusted a test to make sure we were covering that use case and we knew that our tripod mount would be as strong as the rest of it.”

An MV5 condenser and a pair of SRH440 headphones — two thoroughly tested Shure products

Other times, changes in music tastes and the nature of live performances will call for new types of tests.

“There’s always new stuff so we’ll handle a lot of that field testing at the alpha and beta testing level,” Shure Product Specialist Soren Pedersen said. “One that comes to mind is LED walls at big-scale concerts are only a thing as of the last 5 to 7 years and they can do funny things to wireless mics, so that’s something that we tested on when we develop wireless systems.”

No Component Overlooked

Everything that goes into a Shure product gets tested, from microphone capsules, to cables and even buttons. Perhaps more than anything, this small component testing helps to ensure a long life, as these exterior parts are typically the first things to experience wear and tear through normal use.

“Cables are not simple devices…there are a lot of different ways they can fail,” Huertas said.

- Shure’s cable testing station, where cables are pulled over and over again at various angles.

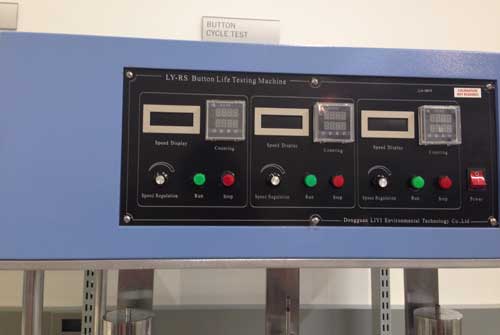

- LY-RS button life testing machine

- A closer view of the button life testing machine

“So testing cables is part mechanical; obviously you want something that is consistent and has the level of stretch that you’re looking for. A lot of it is also statistical,” Huertas said. “So if you notice, the cable test machines that we have are many stations; we’re never just testing one unit or two units, we have statistically significant sample sizes and we look at the output from those tests in order to judge that yes, this is a cable that will match the robustness of the rest of the product.”

Not only does each component that goes into a Shure product get tested, so do the packages that Shure products go into.

“We put our packaging through a certain amount of testing to make sure it protects the product launch shipment and also arrives to the shelf looking good,” Pedersen said.

The testing all culminates in products that not only perform in extreme conditions, but last for years under standard consumer use.

“It’s a huge confidence builder for us, because if we know that a product goes through this crazy barrage of tests that we put it through, it’s going to be fine on Johnny’s desk for 20 years, or the MV88’s going to be fine if you go shoot Pitchfork and it’s 105 degrees with 400% humidity like it always is,” Pederson said.

Pushing The Limits

Of course, testing doesn’t always have to done in a lab coat. Mike Lohman, Shure’s Associate Director of Content and Digital Marketing who goes by “Shure Mike” in many of the company’s testing demos, has come up with a number of unique testing methods that illustrate just how durable Shure products are in a pretty visceral way, including a 200-foot drop from a helicopter.

“That was actually opportunistic,” Lohman said of the drop. “We were having some new HVAC installed on the roof of the building and I said hey can I drop a 58 from a helicopter? And they said yes. They wouldn’t let me go up in the helicopter, but they were up for it.”

The near-legendary ruggedness of Shure products, in particular the SM58, has inspired fans to run their own tests on the ubiquitous mic — one YouTube video tests an SM58 unearthed after being buried underground for a year. We won’t spoil the ending, but you can probably guess what happens…

Photo credit: Shure Corporate Photography.

Leave a Reply